It all started with...

Chainmail, actually. Growing up in New England going to King Richard's Faire in Carver MA became something of a tradition. If you've never been, it's a Renaissance Fair which takes place every weekend from the end of August to the third weekend of October. I would guess that somewhere around 85% of the people who go get dressed up in some way.

When I was in college, my friends and I would make the trip every year and we would always say we should dress up this year! But we never did. We'd get there, find our spot in the massive field they use as a parking lot, and gather up as a group while hundreds of people around us donned medieval armor, clothing, or fantasy costumes of some sort. King Richards Faire is quite literally fantastic fun for the whole family. They have somewhere around 80+ acres of land and the entire faire is within a forested enclosure where they've built a semi-permanent village of sorts. The buildings are rented by individual artisans who all dress up to match the faire, sell their goods and teach people about their trade. There are probably close to a hundred artisans who setup shop at the faire each season. Outside of the artisans there are performers who work the stages spread throughout the enchanted forest, KRF food vendors, and games for all.

We stopped going when the pandemic hit and then a few years ago we decided to start the tradition back up and bunch of us agreed to meet up for the faire. One of our friends was adamant that we dress up this time and so we all went online and purchased some medieval-esque clothing and proceeded to have the most fun we've had yet at KRF. Afterwards I ended up going down the rabbit hole, thanks to the social media algorithm deciding that medieval garb and Renaissance Fairs were my thing, and I found @laurendoescosplay who convinced me that I could build my own shirt of mail. I then proceeded to do an unhealthy amount of research and realized that if I made it out of aluminum (which is typically what people do nowadays if you're not trying to make something which is actual armor) then whatever came in contact with the rings would inevitably turn silver by rubbing against the mail. Most people who endeavor to make their own mail tend to buy pre-cut rings from a manufacturer such as The Ring Lord as it ends up saving you hundreds of hours of work (how much work depends on how big your project is). I however, wanted to save as much money as possible, and I also wanted to make it out of something other than aluminum so that I didn't end up looking like a wish.com version of the tin man.

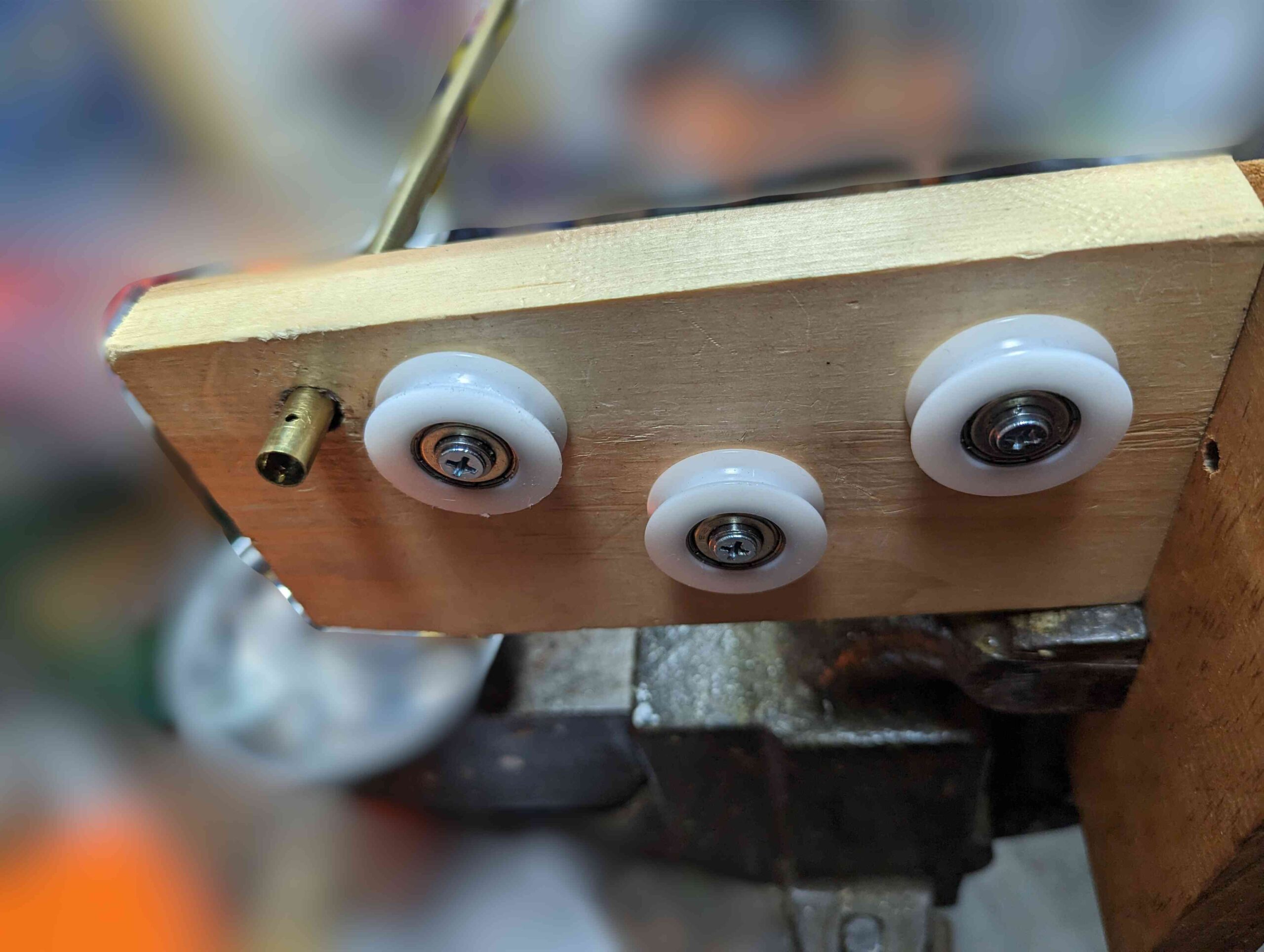

I ended up settling on 16 Gauge 304 Stainless Steel Rebar Tie Wire as my medium so that I wouldn't have to deal with rust or care about the weather and ordered a spool of wire which was 339 feet long. I picked up some KNIPEX bolt cutters and went on Youtube and found someone who had made a jig which allowed them to hook the wire into a metal tube (sized appropriately for the diameter rings you want) and then spin the wire onto that tube which makes a long coiled spring. I recreated that design out of some scrap wood and rollers which I picked up at the local hardware store, ordered a brass tube of the correct diameter and got to work attempting to drill an appropriately sized hole into that brass tube to hook the wire into. I actually live-streamed this process to a couple of friends one night, much to their amusement, as it turns out that drilling a hole into a curved tube is actually quite a bit more difficult than one might imagine. We all had a good laugh at struggle which ensued, and soon enough I had drilled the holes and then chucked that brass tube into my cordless drill. I figured since I wasn't making actual riveted mail armor it wouldn't matter if I cheated a little bit and used the technology I already had laying around to speed up the process a bit:

Once I had built my Jig and started producing the coiled rings I could then snip them off 1 by 1 and then start to assemble them. I spent the next several months doing so in virtually all of my free time:

After having cut over 15 thousand rings I had noticed some issues:

A) When you cut metal with bolt cutters it is not a clean cut - the blades of the bolt cutter pinch the metal and the ends of the rings taper to a point much like this =><=

B) This creates a two-fold issue:

- there can be a burr on one of or both of the ends of the ring which needs to be filed off manually

- there's a gap where the ends of the rings meet which other "closed" rings can slip through if they align just right.

C) This process is incredibly time consuming and repetitive

D) Cutting the rings by hand is hard on your body and could eventually lead to injury

Given these issues I decided to go back down the rabbit hole and see if anyone had managed to figure out a way to saw cut jump rings using some sort of jig that allowed you to cut thousands of rings easily. There was only one commercial product I could find which did this and there was no way I was going to pay over $700 for it - This is a hobby and I'm not selling jump rings or making jewelry. I ended up finding Build It Make It on YouTube and reached out to the creator via his website https://www.builditmakeit.com

He was incredibly helpful and and easily one of the nicest people I have had the pleasure of meeting on the internet. With his help I was able to procure and setup his 3D printed table-saw setup and start cutting some rings!

vs a saw cut which is an extremely thin vertical slice --||--